William Stopford

KGM teases boxy new Ford Ranger rival to replace ex-SsangYong Musso

42 Minutes Ago

Volkswagen is building a new plant for its upcoming Trinity flagship, with construction to begin in 2023 ahead of the car's launch in 2026.

Contributor

Contributor

Volkswagen is building a new factory in Wolfsburg, Germany that’ll produce its upcoming Trinity electric flagship.

Construction of the plant is scheduled to commence in spring 2023 (March to June 2023) and Volkswagen is investing €2 billion (A$2.94 billion) to make it all happen.

The German automaker is aiming to have its Trinity model start rolling off the production line in 2026. At this time, Volkswagen is aiming to produce a Trinity every 10 hours.

Volkswagen says it’ll reach these targets by having fewer components, more automation, leaner production lines and new logistic concepts. It’ll also offer a limited number of Trinity variants to reduce production complexity.

The new plant will be located near Volkswagen’s existing Wolfsburg plant, and the practices implemented here will gradually filter their way into the company’s other plants.

“The decision by the Supervisory Board is an important milestone for the transformation of the brand and the future of the Wolfsburg production facility,” said Volkswagen CEO Ralf Brandstätter.

“We are setting benchmarks in the automotive industry with Trinity and the new factory and turning Wolfsburg into the global lighthouse for cutting-edge and efficient vehicle production.”

Volkswagen says it did consider producing the Trinity in the exisiting Wolfsburg plant but decided it was better for the long term to create a whole new plant.

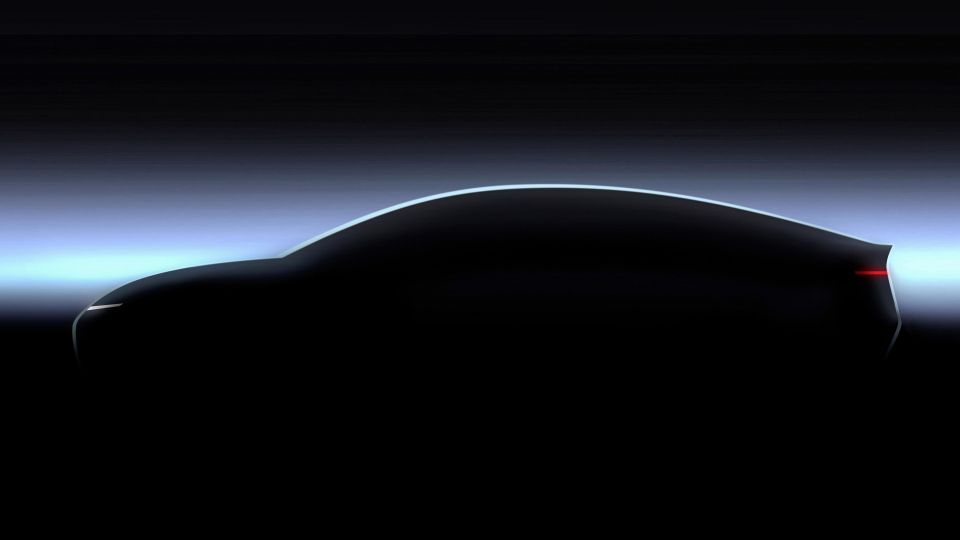

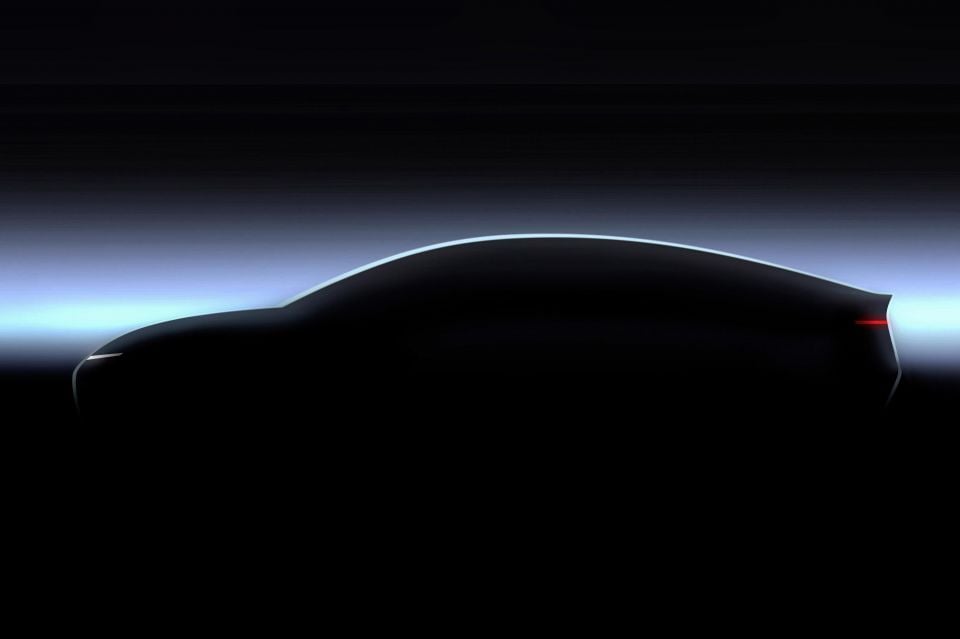

Volkswagen has thus far released a single teaser image of the Trinity.

The render is very dimly lit and shows off a low-slung fastback silhouette.

At the rear of the Trinity, it appears to have a rear spoiler and tailgate somewhat reminiscent of the Skoda Enyaq Coupe iV crossover.

As previously detailed, Trinity is going to be Volkswagen’s flagship electric offering and the company claims it will be net carbon neutral.

Set to be the first vehicle built on the Volkswagen Group’s Scalable Systems Platform (SSP), the Trinity will have an electric range of over 700km, a “shorter charging time” and offer Level 4 autonomous driving.

Over the lifetime of the SSP architecture, Volkswagen is expecting to produce “more than 40 million vehicles” on this electric platform.

This’ll be the successor of not only today’s MEB and PPE all-electric architectures, but also the MQB, MSB and MLB architectures currently used for internal-combustion engine vehicles.

That means it’ll be highly scalable, with models on those existing architectures ranging in size from light hatchbacks (the MQB-based Volkswagen Polo) to full-sized luxury sedans (the MSB-based Bentley Flying Spur).

The Volkswagen Group is also investing €800 million (A$1.17 billion) in creating the “most advanced research and development (R&D) centre in Europe” where it’ll design the core of the architecture and its modules.

MORE: Volkswagen developing ‘Project Trinity’ flagship EV MORE: Volkswagen moving to one unified architecture

Where expert car reviews meet expert car buying – CarExpert gives you trusted advice, personalised service and real savings on your next new car.

Jack Quick is an automotive journalist based in Melbourne. Jack studied journalism and photography at Deakin University in Burwood, and previously represented the university in dance nationally. In his spare time, he loves to pump Charli XCX and play a bit of Grand Theft Auto. He’s also the proud owner of a blue, manual 2020 Suzuki Jimny.

William Stopford

42 Minutes Ago

Josh Nevett

6 Hours Ago

Alborz Fallah

14 Hours Ago

Marton Pettendy

16 Hours Ago

Ben Zachariah

18 Hours Ago

Damion Smy

18 Hours Ago