Matt Campbell

2025 Porsche 911 Carrera T review

5 Days Ago

Alpina is a brand that fascinates enthusiasts. It has a clear ethos, and a range of fast and luxurious cars designed for autobahn blasting. Here, we chat with the boss.

Contributor

Contributor

Alpina is a brand with a small, focused range of cars.

Founded in the German mountain town of Buchloe, it doesn’t have designs on the mass market. It does one thing, and it does it well.

From the BMW 3 Series-based B3 to the hulking XB7 SUV, every Alpina is tuned to travel long distances in comfort at very, very high speeds.

The brand is a tiny player in Australia, but its range is starting to take shape. The XD3 SUV goes head-to-head with the Audi SQ5, while the B5 and B5 Touring offer a more comfortable alternative to the BMW M5.

The new B3 and B3 Touring will be here late this year, while the seven-seat XB7 will follow early in 2021. It’s not a huge leap to suggest a B4 based on the BMW 4 Series isn’t far off either.

At the helm of the company is Andreas Bovensiepen. Although his father founded the company, he hasn’t spent his entire life working there. He’s a fascinating character, equal parts friendly and knowledgeable.

Here, he talks about the history of Alpina, the character it seeks in its cars, his life in motoring, and what the future holds for the brand.

Also on the call were Thomas Cormu, head of product management for Alpina, and Adam Davis, local communications boss.

Andreas Bovensiepen: The typewriter company was founded by my grandfather. But my father started engineering and he said ‘oh, I like cars and I have no connection to typewriters’.

Therefore from the beginning he was never involved in the typewriter business, and he had no interest in it. From the beginning he was interested to build faster cars.

My father was never involved in the typewriter business. The typewriter business was sold, and my father has overtaken the brand name Alpina because our family’s name Bovensiepen is quite long and quite complicated, and Alpina is a shorter name.

It has a connection to the alps, it’s quite easy to speak in English and other languages, so finally he could save this brand name for his products.

AB: As a student my father made some money on the stock market so he bought a Porsche 356, which was a quite sporty car. Not the Carrera, a smaller one – I think it was 90 horsepower or something.

Then he got his first child (I was the first child) and the second child, and he needed a bigger car. He was buying a BMW 1500, which is kind of the size of a 5 Series of today. This car had about 70 horsepower, it was a really lame duck compared to the Porsche.

My father thought ‘oh, we need a stronger engine’, and in Italy Alfa Romeo and Ferrari used so-called Weber dual carburettors, so he bought some Weber dual carburettors and put it on the BMW engine. He worked together with Munich University and engineering department, they helped him a little bit.

Finally he ended up to birth BMW Alpina 1500, and the aim or the target at the time was to sell a lot of carburettor kits, starting with the BMW 1500 but for future BMW products as well.

My father was a little bit lucky, because BMW started with the 1500 but about two years later they came up with the BMW 1800. Some customers who bought one of the later lifecycle 1500 were not really happy, because if they [did not know] that an 800 would be coming.

So finally BMW told them Alpina is making a kit, then you have the same horsepower like our BMW 1800. So if you are not satisfied right now, go to Alpina and buy this carburettor kit and you have a similar fast car. This helped as well a little bit…

The warranty on the basic vehicle was still valid, so BMW tested the carburettor kit and came to the conclusion that Alpina has to warranty the carburettor kit, but the rest of the warranty is still valid by BMW.

This was important, that the whole car warranty was still in place… By some luck, let’s say, my father started with BMW.

BMW still became successful in the ’60s, before BMW was sometimes successful and sometimes not as successful, so it was a little bit of luck to start with a BMW 1500 and as we all know, a little bit later came the BMW 1600, the 2002, and this was a perfect car for racing, and perfect car to make it faster.

So it was a little bit… to be at the right time in the right place, with the right products.

AB: There is this long, long history which is now 55 years – which of course plays a big, important role.

For BMW in the ’60s, of course it was important to prove reliability of the products, so BMW wanted to do racing. But BMW Motorsport didn’t exist at the time, so Alpina got some money from BMW at the end of the ’60s to do racing, and to develop racing cars.

It really started with rally cars, to prepare the cars for the Rallye Monte Carlo and for other rallies, and then my father started early to do the 24 hour race on the Nurburgring, and then in Belgium at Spa Francorchamps.

So Alpina was able to win the 24 hour race overall victory in 1970 at Spa, and Alpina was able to win the 24 hour race on the Nurburgring as far as I have it in my mind ’71, ’72, and ’73.

Three years in a row, victory in the 24 hour race at the Nurburgring was with Alpina cars.

In 1973 Niki Lauda was at the wheel of a Jagermeister Batmobile Alpina and won the 24 hour race at the Nurburgring. There was some funny occasions!

In the beginning of the ’70s Niki Lauda showed up at Alpina headquarters and said ‘I would be interested to drive your racing cars, but I need to register my living here in your small town, Buchloe, because if I’m registered in Austria I have to go to the army and this would not help with my racing career’.

So Niki Lauda at the time was a garage-paying Formula 1 driver, in 1970 he was racing for March – I think 1970 and 1971.

In 1973 he was racing for a small team which was called BRM, and they had the Marlboro sponsor. But Niki Lauda had to pay a lot of money to get this drive, so he was a paying driver. Luckily he was then discovered by Enzo Ferrari for the 1974 season.

AB: He was racing 1970, 1971, 1972, 1973 beside his Formula 1 in touring cars, but at the time it was quite popular that Formula 1 drivers were doing touring car races as well.

For example a very famous race was a six hour race on the Nurburgring Nordschleife. Niki Lauda had the pole position, and he was beating the king of the Nordschleife.

The king of the Nordschleife was always Hans Stuck in the motorsports car.

But on the same occasion, at the same race, Emerson Fittipaldi and Jackie Stewart were racing as well in a touring car, a Ford Capri, because Ford said ‘if we sponsor your engines for Tyrell and for Lotus, the Ford Cosworth V8 engine, then at least one, two times a year Jackie Stewart and Fittipaldi have to race for touring cars’…

It was really funny times in the ’70s.

AB: Alpina was occasionally in motorsports, and won some championships – for example, three times European Touring Car Championship in 1970, ’73, and ’77 – but indeed most of the time Alpina was focused, and is focused, to road cars.

Let’s say the first eight to 10 years it was a side product of racing parts. In the ’60s and ’70s the road cars had four-speed gearboxes but in racing you had five-speed gearboxes. In racing you had a rear limited-slip diff, you had rear axle cooling, you had cooling for the gearbox, for the engine, there were a lot of racing parts which would be sold and later mounted in road cars.

But the beginning of the ’70s – let’s say ’73, ’74 – environmental [rules] got more and more strengthened, and emission rules in fact. Alpina was [working] on injection systems, mechanical injection systems, and went away from the Weber dual carburettors.

It was not the intention to build race cars for the road. It was more the intention to build cars which are very easy to drive fast, which are sporty but [with] a suspension where you can do, let’s say, a 600 mile drive and go out relaxed – not a stiff race suspension.

Today Alpina aims to establish and develop cars which give the customer a lot of pleasure in different senses. So of course the pleasure to accelerate and to have a fast car, but still the pleasure to have suspension which is capable of doing long journeys without any problems to the driver’s back.

It’s a very supple suspension. And of course a car which in comparison to other cars in the same segment has much lower fuel consumption. So more or less, to sum it up Alpina tries to make a very harmonious car in a lot of aspects.

The aspect of an engine that’s not too aggressive. It’s easy to drive with very high torque at low revs, which gives you a certain relaxation so you don’t need to rev the engine high.

Then a very smooth gearbox, eight speed automatic which is very smooth in drive mode, but can be very sporty in sport mode or manual mode so you can shift it on the steering wheel.

Of course you have the finest leather. Lavalina hand-made leather steering wheel, which gives a high-quality feel and a luxurious feel. Still you can have (as a top-of-the line interior) Lavalina – which is a very breathable, natural leather – on your seats, on your whole car which is a very high luxury item.

You can say it’s a very luxurious car, where the competition is more on the side of exclusive brands like Bentley, like Maserati, with the finest leather and a lot of luxury.

Whereas BMW M is very sporty, race car for the road, Alpina is a Bentley or a Rolls-Royce kind of car.

AB: It was not an easy topic, because as you mentioned the X7 is a huge car.

First of all, I have to say BMW has done a great job. It’s really astonishing the car drives very well for such a huge car.

I think what is very important, especially for the German autobahn, is that the XB7 has an active integral steering, steering the rear wheels, which gives the car a very high level of stability at higher speeds.

I was able to drive it sometimes, occasionally, fast on the German autobahn up to 290km/h and if you had a fast lane change it proved to be very, very stable – surprisingly stable. I had the possibility to drive it on the Nurburgring, which was not our main focus, but on one or two occasions our engineers were there to look at the behaviour of the car.

As you know, we always develop special tyres for our Alpina cars. Pirelli has done a great job developing a 23-inch tyre and wheel set.

It’s the biggest so far in the Alpina line-up, 23-inch, and this tyre has a very good performance and grip level so you have not this typically understeering problem which makes the car feel heavy and not agile. The XB7 is not understeering, so the tyre gives the car a lot of agility.

Finally, of course the car has a high centre of gravity, but on this area Alpina worked and we have a two-axle air suspension. We can lower the driving height by 1.6inches, about 40mm, and you can feel it. When you drive the car fast you can feel if the car is 40mm lower. It gives much more stability.

It was a big task to work with the X7, but surprisingly the car is very smooth now, it’s very nice to drive. It behaves much more like a sedan when you’re driving on the road, not like a typical SUV.

AB: For this car the American market is by far the most important market. As you know diesel is no topic in America, or hardly any topic in America, so therefore the decision mainly driven by the American market.

As we know, the Australian market they have a lot of V8 lovers, V8 car guys. We have really a cool sound in the XB7, so I think the Australian customers will like the sound in the car.

Adam Davis: It’s also, the BMW X7 and X5 M50 have moved from diesel back to petrol in Australia.

AB: Sound is a very emotional thing, so Alpina always puts a lot of effort into sound engineering.

Part of our philosophy is to create a sound which is very bassy, very deep, and very V8 typical – versus for example BMW M [which] often has a sound which is more Formula 1 engine-like, high-revving and not a bassy note.

This is a good thing for Alpina to distinguish from the BMW M brand, and from other brands of course. I think altogether how the engine feels, how the throttle response feels, how the suspension feels, the sound…

There’s a lot of small details like I mentioned before with the Lavalina leather steering wheel, and it all sums up that the customer enters an Alpina – let’s say drives five miles – and they can make a statement like ‘oh, I like the car. I feel well. Maybe I cannot say why I feel so well, but everything is in the right place’.

I think this is very important for Alpina, and that customers (at the latest) after you have done your first long journey you will fall more and more in love with Alpina, because the car is so easy to drive. It is not an effort to drive.

If you go back to the ’70s, ’80s, there was some kind of imagining [that] if you drive a Porsche 911 you have to be a man. You have to be a real man, because this is very tough to drive and you have to be very concentrated.

An Alpina is completely vice-versa. We like to make it as easy as possible for the client and for the driver to feel well, to feel safe, and the customers say ‘oh, you can go surprisingly fast but it’s so easy. It’s not demanding for me as a driver, it’s easy’.

If it’s more easy it’s more safe. Let’s say a car has a very wide range, when it starts to oversteer then it’s more easy to control.

If you have a very narrow range maybe it holds, it holds, it holds, and suddenly it’s away and you have hardly any chance to get it. At Alpina we always look at a very wide area where you are safe with the car, and you can correct the car.

It’s not aggressive, it’s more a smooth thing.

AB: As we all know, it’s mainly CO2 and government driven. Still in Europe we have the Paris Agreement, the CO2 has to come down in the car area by 37.5 per cent from today until 2030.

It needs big efforts from the car manufacturers, and from Alpina as well, to reduce the CO2 footprint. Alpina has started to go electric in a small sense, because BMW is starting to integrate a 48V system in more and more engines.

For example we have started right now with the diesel engines in the 3 Series, and in the future of course for the XD3 you have in Australia as well. BMW has integrated a 48V system and we overtake this system. So this is the first steps into electric mobility.

Of course in some years from now probably we will have a hybrid. Of this 48V you can say it’s a mild hybrid, and full hybrid, okay, we are not these kinds of companies who like to be a frontrunner because with full [plug-in] hybrid cars you add a lot of weight.

You add about 250 to 300kg to a vehicle, which is quite difficult to work with concerning agility, because if a car gets more and more heavy you lose agility.

The next thing is, currently full hybrid systems – it’s, let’s say the second generation – and the parts are quite expensive, and the parts are often dimension-wise quite big. I think in maybe two years from now there will be maybe the next generation…

I think it’s currently too early for Alpina to jump out now, but maybe in maybe two or three years BMW and other manufacturers have still better technology. Then it makes more and more sense to enter.

Currently there will be not a quick hybrid car seen from Alpina. It’s too early, but I think we are a little bit in line with BMW or BMW M, with AMG, because there’s no hybrid cars from these kind of performance brands on the market now.

Fully electric cars? In Germany we have the advantage that some of our motorways, some of our autobahns, are unlimited.

If you accelerate hard, and our customers like to accelerate hard and like to go fast, then it’s quite critical with electric cars because it you faster than, say, 120km/h the amount of energy you need goes quickly up. It makes it very difficult with electric cars.

Still the first Germans that have driven the Porsche Taycan in Germany say that if you go in a relaxed style you can do maybe 300km, if you go in a little bit – in Germany if a horse goes a little bit faster it’s called gallop – if you go in a gallop then it’s maybe 200km per battery, but if you go really fast don’t talk about this right now.

They didn’t want to investigate this further, because maybe you can run out of your battery within 100km.

We have a lot of customers who drive 30,000km per year, 50,000km a year. Then it’s difficult. I think a fully electric car makes sense, but more for in-town use and more for a little bit smaller cars.

To go with a really big and heavy car you need batteries weighing, say, 800kg. We can see the best examples in Germany with the Tesla. If a Tesla customer have the car new, he goes about 160km/h in the first four weeks.

But then you see the guys, they know the battery goes down so quickly, they stay in the bracket between 100km/h and 120km/h and don’t go fast. They don’t accelerate hard because they know it’s not fun always to have a battery recharge, and you need a lot of time to do so.

Currently I would say it’s not the Alpina customer, a fully-electric car. But maybe in strictly speed limited countries, in California maybe it would work. Why not?

But in the majority of the countries we sell our cars, I think it’s not today. Maybe in 10 years.

AB: Not really, indeed. Okay sometimes if maybe they are tired after an office day, I will not say an Alpina client is always going fast, fast, fast, but most of the time he likes to have the possibility to do so.

And of course a mechanical engine, a mechanical engine noise, it’s some very emotional thing. I think it’s much more difficult with an electric, with an electric acceleration or electric sound of a car… it’s not an emotional sound.

You can compare it to watches. In the beginning of the ’70s the quartz watch, the electronic watch came up, and everybody thought now the Swiss watch industry and the high-class watch industry will die.

It did not happen, still today there are people who have some money, they like to have a mechanical watch on their wrist and like the mechanical watch.

I think it’s a bit like this with cars, or I hope so it will be like this in the future (in five years or 10 years) there’s maybe a certain amount, a certain percentage of cars – let’s say 10, 20 per cent of cars – where the people love still to have a mechanical engine, like with a watch.

Thomas Cormu: I think we will have the XD3 at the beginning of next year. More information to come until the end of the year.

AB: We are our own company. We have negotiated, like for example Aston Martin or McLaren, we have negotiated our own roadmap to go down with emissions with the European Commission.

We have targets and we have to lower year-by-year, but we have not as strict targets like BMW because we are in a different segment, like Aston Martin, like McLaren. If you build only big cars with engines starting with six cylinder you cannot fulfil the strict targets like the big manufacturers have to do.

There is a rule that if, for example, you sell less than 1000 cars in the European community then you don’t have to fulfil the CO2 emissions. But we are quite close to this, and of course maybe we will sell more than 1000 cars in Europe only in the near future.

Therefore we have to fulfil certain targets. You can a little bit compare when the European car industry has to go down 37.5 per cent within the next 10 years, more or less we have to do the same but we are starting from a much higher level.

AB: Currently we are fine. That’s the reason we have, especially in Germany, we have a line-up of diesel cars like the new D3 is coming in the 3 Series, and we have the XD3, the XD4 as a left-hand drive.

We have a 5 Series diesel, and with these kind of diesel we are right now. Within the next years we are able to fulfil the CO2 footprint, but of course in five years from now we at least need a hybrid car or fully electric car in our line-up to fulfil the emissions rules.

In some years from now we have to decide whether to develop our first hybrid, or alternatively a 100 per cent electric-powered vehicle, otherwise we are not able to fulfil [the regulations].

If we would have one car in our line-up as a hybrid or as a fully-electric, then still we can survive some years. Because one car would help us come down and then we can stay in the other segments with our petrol and diesel-driven cars.

We have not a need to have a hybrid or electric car in every line-up. We don’t need, let’s say, a 4 Series electric car, a 5 Series electric car, a 7 Series electric car. If we would have a 5 Series hybrid and we would have a certain volume which we sell, then it would help us for some years.

AB: A plug-in hybrid, yes indeed. I’m talking about either a fully electric car in the line-up, and we could stay the rest petrol-driven and diesel-driven, or alternatively to make a plug-in hybrid in a certain number.

Today our diesel cars are around 170g/km of CO2, and the B5 is about 270g/km. If we would have a hybrid it would be around 60g/km or 55g/km, and this would help a lot to get the whole fleet down.

One car in a certain volume would help you a lot to get your fleet number down. We currently have to say, in the current generation, there’s a lot of compromises to do [a PHEV].

If you have a plug-in hybrid you have a very small fuel cell, then you get a smaller range and Alpina customers often need to have a high range because they drive high mileage.

The second thing is you have still some disadvantages in luggage space in the luggage compartment if you’re buying a hybrid today. And in the future these kinds of problems with better technology, that needs less space in the car, can be overcome.

Not 100 per cent, but to a certain extent.

AB: Development of course takes place completely at Alpina, at our premises with our team of about 70 engineers.

CAD, application, software… And we are using of course the BMW testing facilities like Miramas in south France, near Marseille. And they have a testing centre near Munich.

For high-speed testing we go to south Italy, there is an (I think) 12km circle where you can go high speed, speeds of 330km/h. It’s called Nardo, you probably know Nardo.

We have our engineers, but we use BMW facilities and of course we use the German autobahn. It’s very important to drive a lot of kilometres in the development time on normal roads, on secondary roads, on motorways as well.

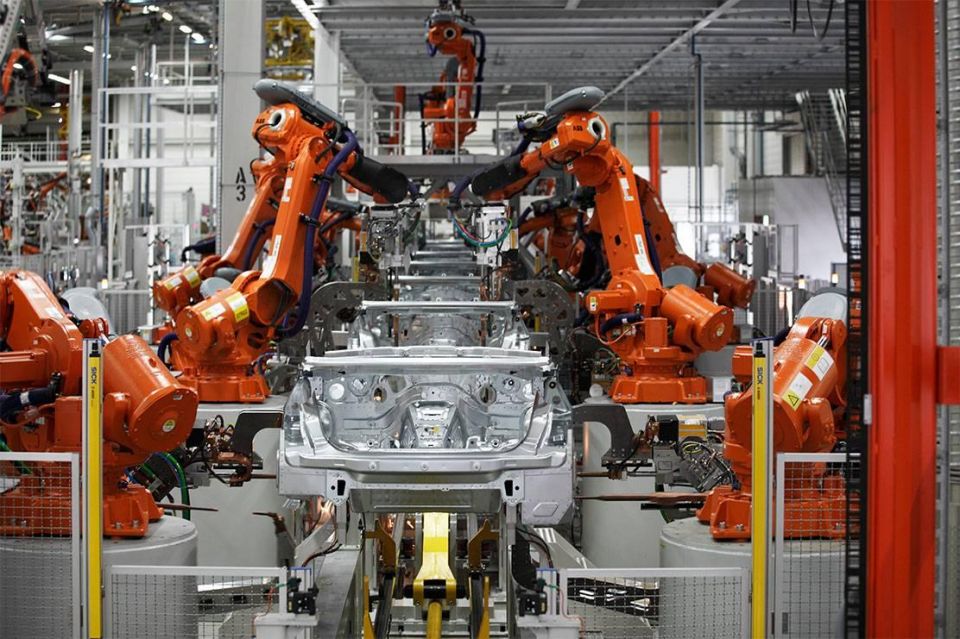

Probably what you aim on is our integration with BMW in the plants. In the ’60s and ’70s and beginning of the ’80s Alpina bought the completely standard BMW and put it into pieces. Changed the exhaust system, the wheels, the brake calipers, the steering wheel, a lot of parts in the engine, different gearbox, bigger differential…

This was quite costly, and the competition gets more and more severe. Then of course we looked out for solutions, that we could be integrated, and this started from the middle of the ’80s.

We deliver a bunch of Alpina parts to the assembly line in Germany, or maybe even Spartanburg in South Carolina. Today we deliver our engines to the plants, ZF delivers the Alpina-modified gearbox, we deliver our wheels, Brembo delivers Alpina-modified and painted calipers to the assembly line.

More or less 80 per cent of the Alpina car is still produced in the BMW plants, but every car comes to our premises for final production. For example, we have to put on the front aerodynamic parts, front spoiler, rear deck spoiler.

Of course every Alpina gets the Lavalina finest leather steering wheel. Especially in Europe a lot of people are like ‘oh I like the headrests with Alpina stitching, or the Alpina emblem’. So there’s a lot of small details.

It’s not always a complete leather interior, but it’s often some details customers like to specify. This has to be done in our premises. This is indeed a very unique situation, because only Alpina is integrated in the BMW plant.

No other tuner has the integration there.

AB: For this reason our competition, or our main competition, is AMG and Audi S and RS models, and of course Maserati, Bentley – these kind of companies.

We don’t see any competition in the tuning area.

AB: I started in 1982 with some kart racing, and in 1984 I was third in the European kart championship.

Then I did a competition, there was a German magazine called Sport Auto and they were looking for a driver they wanted to support until touring car racing, or DTM racing. I was part of this competition.

There were about 1000 people applying to get a racing driver, and I finished in this competition in third place. I won some kart racing, but the big karts, the 250cc karts who race on the real racetracks.

I did this competition and finished second as well, so finally I ended up in Formula Ford in 1985 and ’86, and I finished third in the German Formula Ford championship.

Another driver who became quite famous and who won, I think, Le Mans three or five times was Frank Biela who was the Audi works driver, and became DTM champion for Audi. [He won five times between 2000 and 2007]

I was racing more or less up to DTM level in 1987, where I was racing an Alpina race car but to be honest I started a little bit late, so finally I wasn’t as talented like Michael Schumacher.

I’m not bad, but I’m not good enough to win on DTM level – I was good enough to have some top 10 finishes in DTM racing, and I was able to win the 24 hour race on the Nurburgring in 1998 on a BMW race car.

AB: It was Hans Stuck and Mark Duess, a Belgian race driver. This was a very interesting race, this was the time that BMW had a new range of diesel engine with common-rail injection, and they wanted to prove that still with a diesel engine you can be successful with racing.

It was before Audi started with Le Mans racing efforts. The car was called STW, this was the 2.0-litre touring car racing series, but in this kind of race car BMW built in a racing engine with a diesel.

At the time it was an experimental engine with 200hp, and a torque of about 450Nm which was a torque like a normal-aspirated V8 engine.

With this engine we competed against a lot of Porsche 911s and BMW M3s, and still Lamborghini was racing in the 24 hour race at the time, but we had the advantage of racing three and a half hours before our first refuelling stop. This was quite demanding, because there was no servo steering.

It was a manual steering, and after three and a half hours you got big, big arms because it was quite demanding. But the car was really fast in cornering, and of course a lot of torque. We had some rain as well in the race, so it was very mixed up as a 24 hour race and we were able to manage to win this race overall.

This was the first diesel victory in an international car race, it was before Audi won Le Mans.

I started business administration, and additionally I have a technical background as well. I started in the beginning of the ’90s with a supplier for carbon fibre parts, who made a lot of parts for DTM racing and for Recaro, for racing seats.

Middle of the ’90s I joined BMW in development. The first two years I was working in the suspension department to set up BMW suspensions for BMW E46, BMW Z3, and I came in contact with the BMW Z8 as well, where I worked on the suspension.

Then the guys asked me at BMW… asked me whether I want to work as the right-hand of the project leader of the BMW Z8.

I was working in the development of this car at BMW, at the BMW Munich headquarter in the Fiz development centre. I was working to bring this car, the BMW Z8, into reality and we developed an Alpina version – which was my idea – with a V8 engine and an automatic gearbox, which was very important for the American market…

Then I worked within BMW from 2000 until 2002 in the marketing department for the 3 Series and 3 Series coupe, E90 to E93. After this time I entered at Alpina in 2002.

So I have a lot of knowledge in engineering and sales and marketing, and I know a lot of people at BMW in engineering as well. This helped a lot of course, and probably helps us today because Alpina is a very small, dedicated team.

If you tell your team what is your requirements, and still you can drive with engineers from time-to-time and tell them I like this suspension, or this behaviour of the tyre, I like this not as much… you can go quite quickly to a result which is convincing.

Thomas Cormu: We started actually with the last B3, and the model was at the end of its lifecycle, so it was quite complicated.

Of course the brand Alpina is not well known in Australia, which is also very difficult for us, but then we launched the XD3 which fits the Australian quite well. The car is selling well. It’s not big numbers, but I think we have a very good niche product with the XD3.

We are establishing the brand with this product. We launched the B3, the new B3, especially with the Touring version. We have very good feedback from the market and from our importer as well, and I think we making some progress.

It’s a tough market, it’s very aggressive in terms of pricing. But I think with the product portfolio that we now have with the XD3, the new B3, and the XB7, I think that we have the right portfolio in order to get some momentum.

AB: Alpina cars, still if we compare it in Europe, our customers are a little bit older than a typical M customer. In Europe you have much more the kind of ‘hide a little bit your car’, a lot of understatement. Not everybody should see that I have an expensive car.

I think this is completely different in Australia, and maybe in the United States of America, so the people like much more to show what they have. This of course is for Alpina a little bit more difficult, because exterior-wise and design-wise we are much more understated than an AMG car, for example.

Therefore we need much more time to convince the customers to buy an Alpina car. I could imagine when a customer for the first time had an Alpina car probably he is satisfied with the car, and he will buy again an Alpina car. But we need a little bit more time to get in this situation.

And with the trend of having more and more SUVs, like the XD3 and now the XB7 which is important for Australia as well, I think we have a chance to build up more momentum.

Of course we will never be a big, big player. It’s always a niche car.

Especially in Europe, Alpina customers when we ask in surveys ‘why did you buy an Alpina?’ the customers answer: ‘I like the exclusivity of the brand, I like a car which is not on every corner. That’s a main reason I bought the car. And I like very much the overall harmony of the whole Alpina concept’.

I think there is still a lot of work on the marketing side to do, and as more journalists drive Alpina cars. We need some more years to develop, but we are optimistic.

Where expert car reviews meet expert car buying – CarExpert gives you trusted advice, personalised service and real savings on your next new car.

Scott Collie is an automotive journalist based in Melbourne, Australia. Scott studied journalism at RMIT University and, after a lifelong obsession with everything automotive, started covering the car industry shortly afterwards. He has a passion for travel, and is an avid Melbourne Demons supporter.

Matt Campbell

5 Days Ago

James Wong

4 Days Ago

Max Davies

3 Days Ago

Josh Nevett

2 Days Ago

Josh Nevett

1 Day Ago

William Stopford

15 Hours Ago