Max Davies

2025 GWM Haval H7 review

5 Days Ago

The term ‘MQB’ is commonly used when talking about cars made by the Volkswagen Group. But what does it mean, and what is it?

Contributor

Contributor

Platform sharing is a widely thrown around concept in the car industry today.

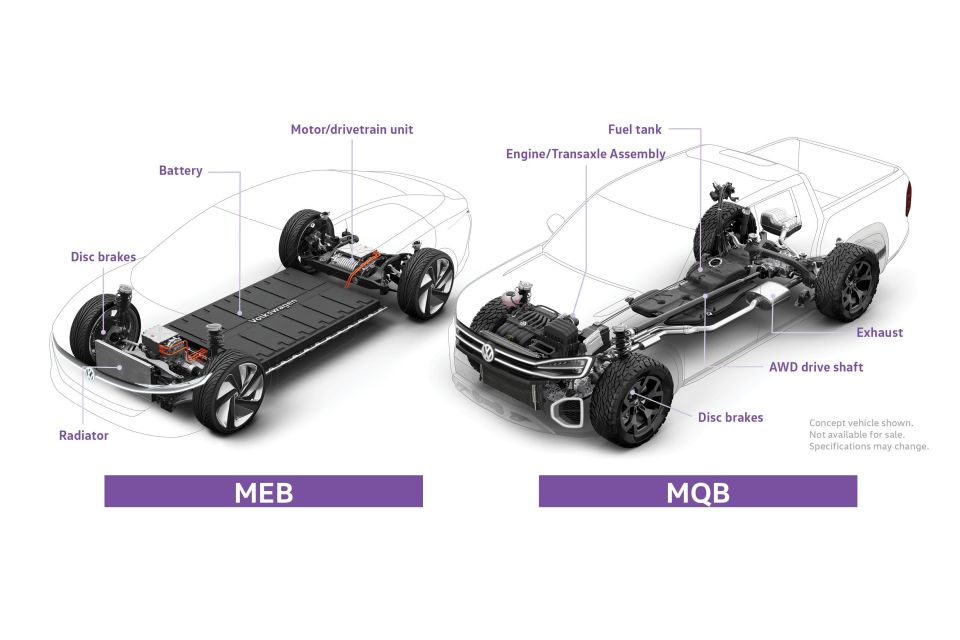

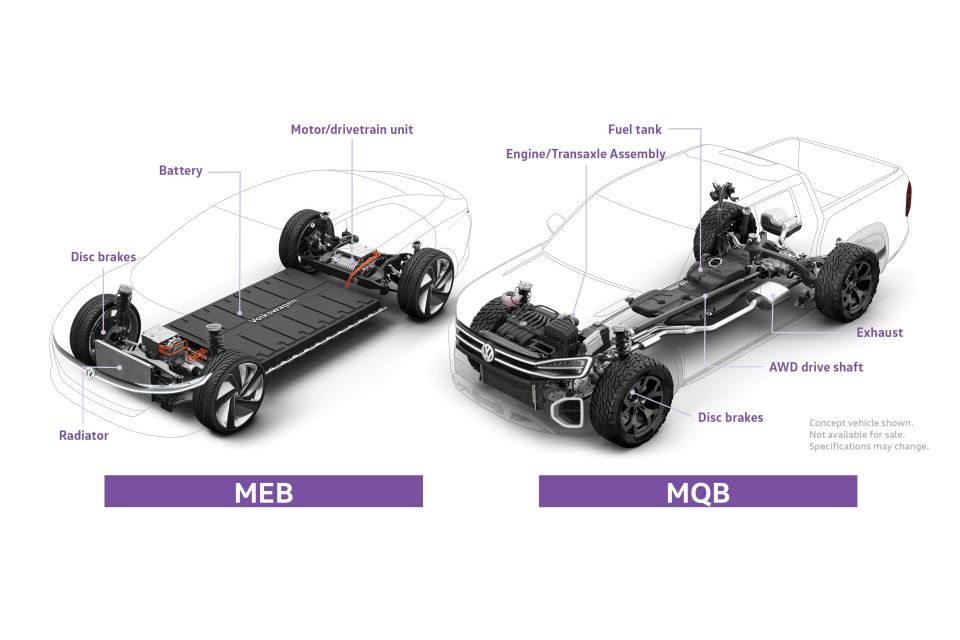

Although the term ‘platform’ traditionally refers to a chassis, today it’s a broad concept referring not only to chassis, suspension, and associated mechanicals, but also drivetrains, electrical, and infotainment systems within a range of different vehicles.

That’s why Volkswagen doesn’t necessarily refer to MQB as a platform. Instead, it’s a ‘toolkit’ that can be assembled in a huge variety of ways.

In German, the acronym MQB stands for Modularer Querbaukasten, translating to Modular Transverse Matrix.

The clue to what MQB means lies in this name – it is a modular, adaptable system to engineer and build cars.

All MQB cars are have a transverse-mounted (the engine is parallel to the axles in an east-west layout) engine at the front, paired with front-wheel drive or front-biased all-wheel drive.

Volkswagen began developing MQB around 2008. Taking four years to develop and involving an investment of over $90 billion, it debuted in mid-2012 with the launch of the third-generation Audi A3, and remains in use throughout various Volkswagen Group brands and line-ups.

MQB succeeded a variety of platforms, including the PQ25 platform for light cars (older Polos), the PQ35 platform for small cars (older Golfs), and the PQ46 platform for medium size cars (older Passats).

MQB cars can vary greatly in size, with vehicles offered in everything from the light car/supermini segment, all the way to seven-seat large SUVs.

All MQB cars share the same distance from the front axle to the firewall, and identical mounting points for the engines (regardless of petrol, diesel, or hybrid).

To create larger or smaller vehicles, the dimensions of other parts of the car can be varied, such as the wheelbase and front and rear overhangs.

In each case, the MQB parts bin allows for standardised, interchangeable components, in turn facilitating common production processes regardless of the car being produced, the factory size, or its location.

MQB cars may also share engines and transmissions, with Volkswagen claiming it reduces the number of possible engine and transmission combinations by 88 per cent. Even electrical architectures and infotainment systems can be shared.

The primary advantage of MQB is cost efficiencies and other savings that will outweigh the substantial initial investment into the platform.

Volkswagen CEO Herbert Diess has claimed the firm will be able to use MQB for at least three generations of vehicle without substantial additional investment, with models such as the recently-unveiled Mk8 Golf and Skoda Octavia sitting on an updated ‘MQB Evo’ platform perhaps representing the second of these generations.

With countless front-wheel drive, transverse-engine Volkswagen Group models being produced at factories around the world, MQB is predicted to substantially reduce development costs of new models.

By investing in a single high-quality part that can be used in multiple models, rather than spreading resources to develop similar but non-interchangeable parts, MQB also increases scope for enhanced vehicle quality and durability.

Although MQB is flexible and allows for different wheelbases, overhangs, and even track widths, some vehicles may be limited by the fact they’re built on shared bones instead of an optimised, bespoke design.

Predetermined mounting points and fixed requirements for the distance from the firewall to the front axle, for example, limit design and engineering freedom.

Being able to accept multiple types of drivetrain also reduces the degree to which MQB cars can be optimised for each one. For example, MQB-based vehicles have been offered with electric powertrains (such as the VW e-Golf), but the platform remains geared towards combustion-engine cars.

Battery-electric variants can’t offer the same space or practicality advantages of car built on a dedicated EV platform.

Of course, with the launch of the dedicated MEB platform for electric cars, Volkswagen is unlikely to launch new electric vehicles on the MQB architecture.

Currently, the majority of small to medium cars sold by the Volkswagen Group’s mainstream and premium brands make use of the MQB platform.

In Australia, this includes everything from the latest Volkswagen Polo and Audi A1, all the way up to the Volkswagen Tiguan, Skoda Octavia and Superb, and the Volkswagen Arteon.

In America, the MQB platform has been stretched even further to develop the VW Atlas, a seven-seat SUV slightly larger than the Touareg.

For more expensive, luxurious models, Volkswagen uses a series of alternative shared platforms.

These include the MLB platform (Modularer Längsbaukasten, or Modular Longitudinal Matrix) for vehicles with longitudinally-mounted engines and either front- or all-wheel drive, such as the Audi A4 and Q5.

For the latest Porsche Panamera, as well as Bentley Continental GT and Flying Spur models, Porsche and Bentley jointly developed the MSB platform (Modularer Standardantriebsbaukasten, or Modular Standard Drivetrain Matrix) for rear-wheel and rear-biased all-wheel drive vehicles.

With the Volkswagen Group rapidly pivoting to electric vehicles with the launch of the ID. 3 and ID. 4 and associated derivatives from Audi, Seat, and Skoda, it’s likely MQB may be supplanted in part by the MEB platform, which applies a similar idea to vehicles that are exclusively battery electric.

Where expert car reviews meet expert car buying – CarExpert gives you trusted advice, personalised service and real savings on your next new car.

Max Davies

5 Days Ago

Josh Nevett

4 Days Ago

Josh Nevett

3 Days Ago

Paul Maric

2 Days Ago

William Stopford

2 Days Ago

Damion Smy

1 Day Ago