Max Davies

2026 GWM Cannon Ultra review

6 Days Ago

News Editor

Tesla’s next-generation vehicles will enter production in Mexico in 2025, per a report out of China.

According to a translated report from LatePost, published on social media site Weixin, Tesla will start production in the Monterrey, Nuevo Leon plant during the first quarter of 2025.

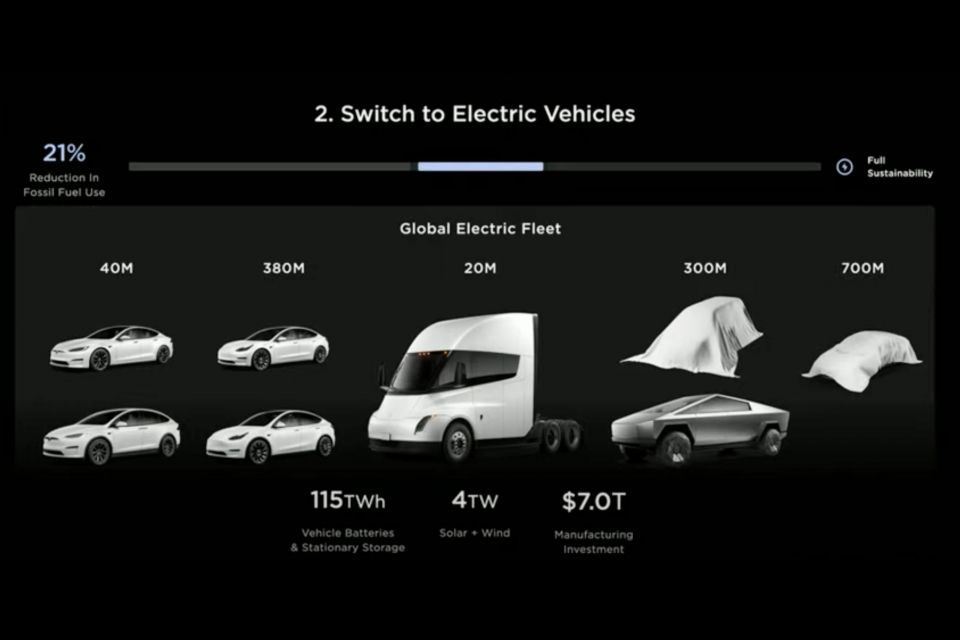

This plant has previously been confirmed by Tesla to manufacture its ‘next-generation’ vehicles, and the company has previously said it’s working on a smaller, more affordable vehicle to slot in under the Model 3 as well as a robotaxi.

Elon Musk spoke of a new entry-level model back in 2020, with a mooted base price of US$25,000 (A$37,638 in today’s money) and “fully autonomous” capabilities.

Tesla’s cheapest model at present is the Model 3 RWD, which opens at $61,300 before on-road costs. Chinese brands like BYD and MG are making inroads in the local electric vehicle market with models that start well below that.

A production start date of 2025 is later than expected, with people close to Tesla’s suppliers telling the Chinese outlet the automaker had underestimated the difficulty of building a factory in Mexico.

Tesla has reportedly given suppliers a target to start localised production in Mexico before 2025, or risk losing orders for not only parts for Mexican-built Teslas, but also those vehicles built in the US.

The Mexican plant will produce two million vehicles annually and, per a report from Mexican media outlet Reforma, Tesla is investing US$10 billion (A$14.76bn) into the facility.

For context, Tesla produced 710,000 vehicles last year at its Shanghai factory, with Model 3s manufactured there using 95 per cent Chinese-sourced parts – most reportedly coming from factories within 300km of the factory.

LatePost reports more than 20 of Tesla’s Chinese suppliers have announced plans to build factories in Mexico, or have already built factories there in preparation for the new vehicles.

Mexico is the fourth largest producer of auto parts and the sixth largest producer of automobiles in the world, and is home to factories belonging to BMW, Ford, General Motors, Nissan, Stellantis, Toyota and Volkswagen.

Mexican President Andres Manuel Lopez Obrador confirmed earlier this year his country had been selected as the location of the next Tesla plant, following the automaker’s plants in the US, Germany and China.

While his announcement came just before Tesla’s 2023 Investor Day, the automaker didn’t go into too much detail about the next-generation vehicles themselves.

“Elon alluded to the fact that Mexico will build our next-gen vehicle, but we will also be doing that in our other plants,” said Tesla’s vice president of vehicle engineering, Lars Moravy.

“And so it’s really about getting them all up and running. We expect that to be a huge volume product, and we’re gonna move that quickly over the next couple of years.

“Our next generation platform is more than one segment and it’s really worth thinking about all the segments that are available that we haven’t captured and where the market would be, in designing it with our supply chain partners so that we can go quickly through those segments for where we need.”

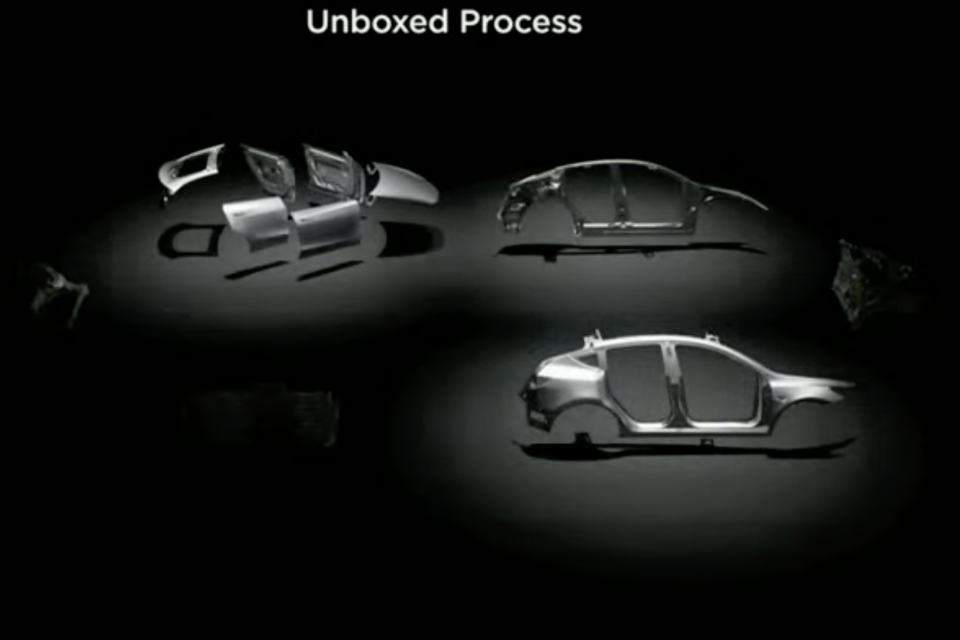

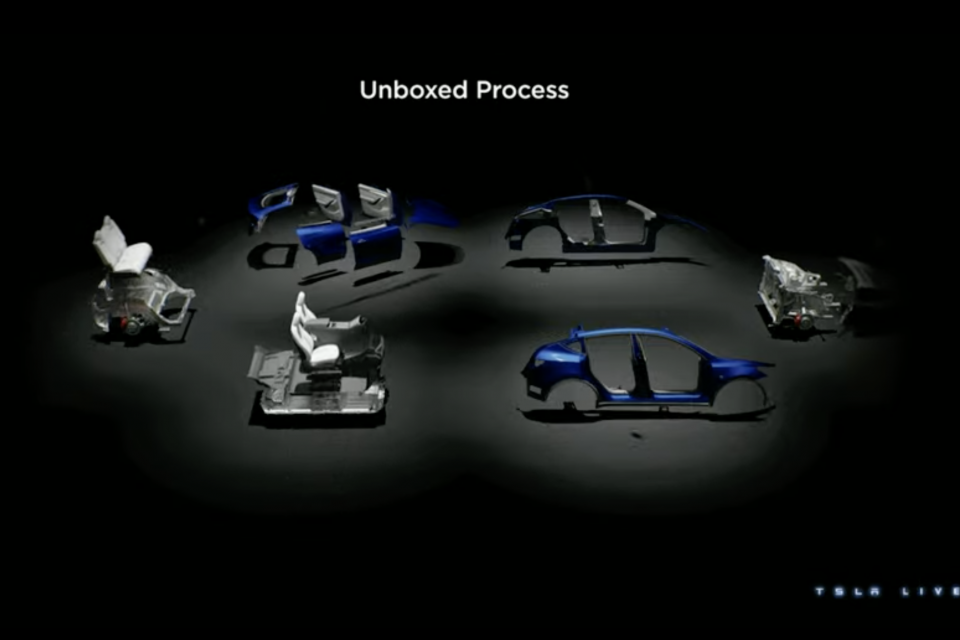

While details on what shape the next-generation vehicles will take weren’t forthcoming, the company did detail the new production process that could cut costs by up to 50 per cent.

“Cost reductions don’t come from any one place… We have to go through everything,” said chief financial officer Zachary Kirkhorn.

The company said further cost savings will be found in the robotaxi version of the next-gen model.

Tesla says it already took out 50 per cent of costs from its Model S and Model X to its Model 3 and Model Y, and wants to do it again.

It says past Tesla vehicles were designed first, then engineered, then manufactured. But with the next-generation model, it wants to bring the design, engineering and manufacturing teams together at the beginning.

The company pointed out the inefficiencies of the traditional way of manufacturing a vehicle, saying it’s at “the tail end of its manufacturing optimisation” just over 100 years since Henry Ford opened his first assembly line.

Tesla could keep costs down with its new 4680 batteries, first announced in 2020, which are said to be both more energy-dense and affordable to produce.

The company confirmed in December it had reached a weekly production output of 868,000 cells, which it says is enough to power 1000 vehicles.

Where expert car reviews meet expert car buying – CarExpert gives you trusted advice, personalised service and real savings on your next new car.

William Stopford is an automotive journalist based in Brisbane, Australia. William is a Business/Journalism graduate from the Queensland University of Technology who loves to travel, briefly lived in the US, and has a particular interest in the American car industry.

Max Davies

6 Days Ago

Josh Nevett

4 Days Ago

Max Davies

4 Days Ago

Max Davies

3 Days Ago

Neil Briscoe

2 Days Ago

Max Davies

16 Hours Ago