Shane O'Donoghue

2025 Nissan Ariya Nismo review: Quick drive

5 Days Ago

General Motors has inked a deal with an Australian raw materials supplier to source nickel and cobalt for its next-generation electric vehicles.

Contributor

Contributor

Next-generation General Motors electric vehicles (EVs) will feature nickel and cobalt from Queensland in their battery packs.

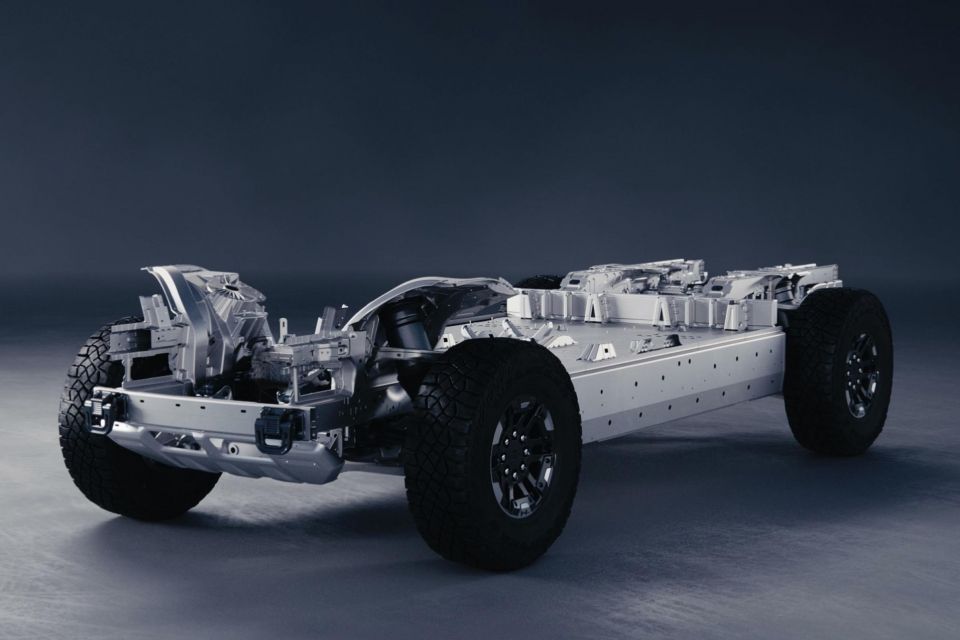

A new partnership between GM and Queensland Pacific Materials (QPM) will see the Australian raw materials used to build the Ultium lithium-ion battery packs that’ll feature in everything from the Chevrolet Equinox EV to the GMC Hummer EV truck.

The deal with QPM follows the inking of a deal to buy cobalt from a Glencore mine in Western Australia.

The General plans to have an annual EV production capacity of 1 million units by 2025 in the USA, built using a new battery architecture dubbed Ultium.

“The collaboration with Queensland Pacific Metals will provide GM with a secure, cost-competitive and long-term supply of nickel and cobalt from a free-trade agreement partner to help support our fast-growing EV production needs,”said Jeff Morrison, GM vice president for global purchasing and supply chain.

QPM will gain up to $US69 million ($A110m) in investment from General Motors to help “accelerate nickel production” at its proposed Townsville Energy Chemicals Hub (TECH) in Townsville. Construction is slated to begin in 2023.

When it’s up and running the TECH project will take nickel laterite ore from New Caledonia and, using a patented “refining and recycling process called the DNi Process” will extract “nickel, cobalt and other precious metals from the laterite”.

“GM’s investment in our company and the associated offtake brings us one step closer towards construction of the TECH Project where we will one day aim to deliver the world’s cleanest produced nickel and cobalt,” said Stephen Grocott, QPM CEO.

“We thank GM for their belief in our TECH Project and look forward to becoming part of the GM sustainably sourced raw material supply chain.”

General Motors is launching a slew of dedicated electric vehicles across its Buick, Cadillac, Chevrolet and GMC brands, having started with the Ultium-based GMC Hummer EV and Cadillac Lyriq.

Scott Collie is an automotive journalist based in Melbourne, Australia. Scott studied journalism at RMIT University and, after a lifelong obsession with everything automotive, started covering the car industry shortly afterwards. He has a passion for travel, and is an avid Melbourne Demons supporter.

Shane O'Donoghue

5 Days Ago

Anthony Crawford

4 Days Ago

Matt Campbell

3 Days Ago

James Wong

2 Days Ago

Max Davies

1 Day Ago

William Stopford

19 Hours Ago