Andrew Maclean

1 Month Ago

Founder

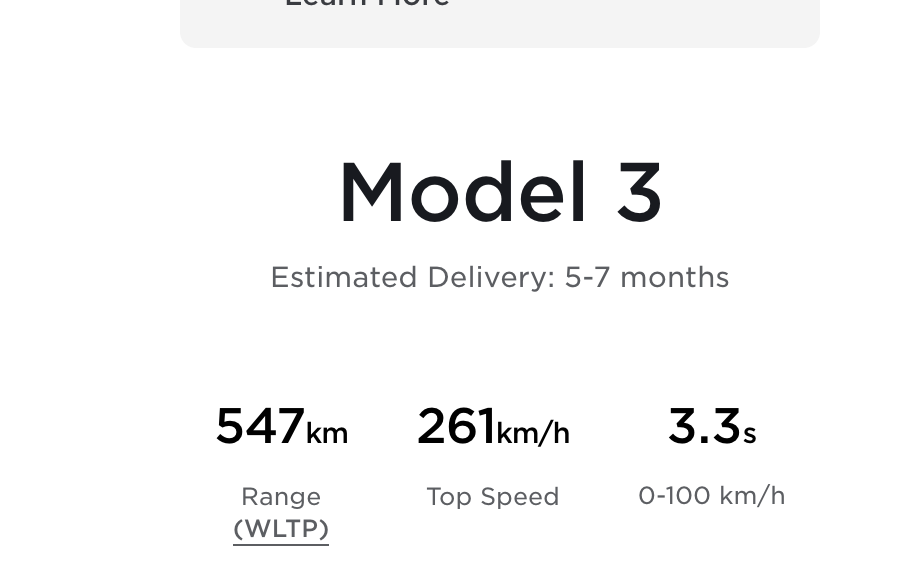

Well, that escalated quickly. Buyers wanting to get their hands on any Tesla Model 3 variant now have to wait up to seven months while the company catches up on outstanding orders.

The latest development builds on the 20-week wait previously reported for Australian orders of the Model 3 sedan, which is built in China for the local market. Although you’ll have to wait, Model 3 orders are still open.

Estimated wait times have, however, been removed for the Model S sedan and Model X SUV, the updated versions of which are now not expected to arrive to Australia until 2023 or 2024 as Tesla pushes to meet global demand.

The Model Y, the Model 3-based SUV, was expected to go on sale in Australia in 2021. Evaluation vehicles were reportedly shipped to Australia for certification, but that hasn’t materialised either.

Tesla had previously appeared to be immune to the semiconductor crunch hitting carmakers, but it now appears to be catching up with the electric car manufacturer.

Last week a report by CNBC suggested Tesla has removed one of the two electronic control units from the steering racks of Chinese-made Model 3 and Model Y vehicles, which will prevent more sophisticated autonomous driving technology from being deployed over-the-air.

Last year, Tesla removed lumbar support from Model 3 and Model Y vehicles due to the chip shortage. Elon Musk had said during an earnings call in January 2021 his company was having difficulty sourcing chips for this feature.

Musk has griped publicly about the chip shortage, calling 2021 “a supply chain nightmare”.

Other companies have removed features due to chip shortages, including Peugeot dropping side airbags from its Expert van, and BMW Australia removing touchscreen functionality from the 3 Series.

Tesla has also delayed the launch of its much-anticipated Cybertruck and Roadster models, blaming supply chain issues.

CarExpert does the hard work to get you the best price. No negotiating, no hidden costs, just expert help and real savings on your next new car.

Paul Maric is an Australian car expert based in Melbourne, Australia. Paul is a founder of CarExpert.com.au & formerly part of the CarAdvice founding team.

Andrew Maclean

1 Month Ago

Anthony Crawford

1 Month Ago

Max Davies

1 Month Ago

Josh Nevett

1 Month Ago

Josh Nevett

15 Days Ago

William Stopford

12 Days Ago