James Wong

2026 Audi Q5 review: Quick drive

6 Days Ago

Solid-state batteries are often touted as the holy grail of electric vehicle battery technology, but what makes them so desirable?

Contributor

Contributor

With electric vehicle charging infrastructure in Australia still in its infancy, one of the main concerns consumers have with buying an electric car is their limited range.

Solid-state batteries have long been proclaimed by several car manufacturers as the battery to end all batteries. A breakthrough technology that offers dramatic advances in range, safety and charging speeds.

Given all this hype, how do they work and why aren’t EVs using them already?

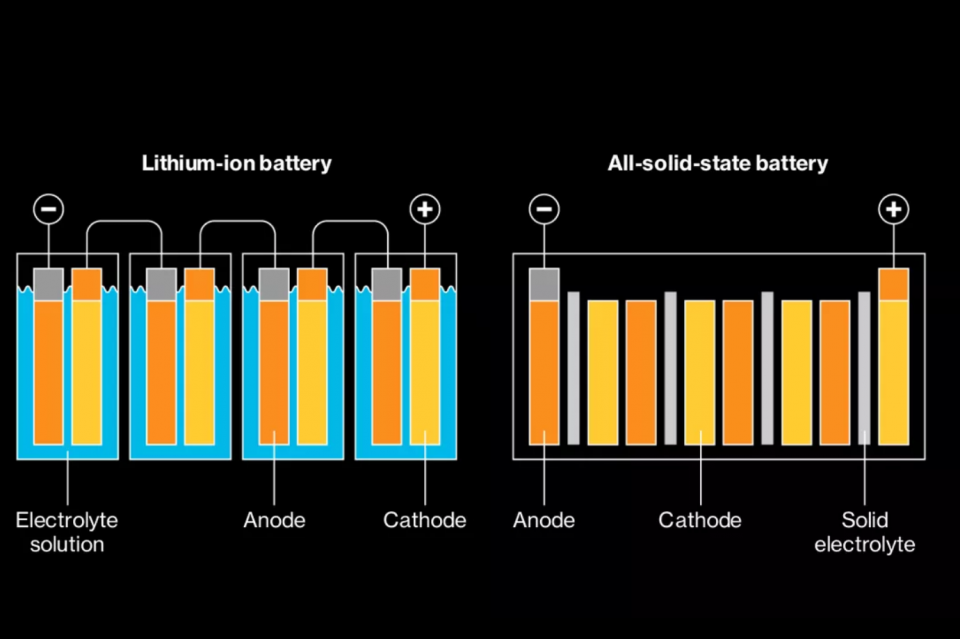

Most electric vehicles sold today make use of lithium-ion batteries. Today’s lithium-ion batteries incorporate a liquid electrolyte to stimulate the transfer of electrons from the anode to the cathode, through a redox reaction. As the name suggests, a solid-state battery works on the same fundamental principle, but uses a solid, rather than liquid, electrolyte.

Note that as ‘solid-state’ refers to the electrolyte, lithium-ion batteries and solid-state batteries are not mutually exclusive terms. As described below, it’s possible for a lithium-ion battery to make use of a solid electrolyte, and therefore be accurately described as a solid-state battery (such as a thin film lithium-ion battery).

MORE: Electric car battery chemistry: What’s the difference?

Solid-state electrolytes such as silver sulphide have been observed since the 19th century. During the 20th century, various technical advances were made, with arguably the most important of these being the development of the thin film lithium-ion battery during the 1990s. This is a form of solid-state battery that is presently being used in various small electronic devices such as RFID tags and smart cards, as well as medical devices such as pacemakers and implantable defibrillators (ICDs).

There are currently no mass-market EVs that make use of solid-state battery technology. The closest relation is perhaps the Mercedes-Benz eCitaro bus. A trial of 21 EV buses powered by solid-state batteries was undertaken in the German city of Wiesbaden earlier in 2021, however all buses were recalled due to a risk of the batteries short-circuiting.

A new shipment of solid-state battery powered articulated eCitaro buses was subsequently delivered to the German city of Hamburg in June 2021. These models are operational, and make use of a 441 kWh battery to provide an operating range of approximately 200km.

The primary benefits of a solid-state battery stem from the solid composition of the electrolyte.

One of the most significant benefits might be safety. In an extremely severe collision, conventional lithium-ion batteries may leak and catch fire, as the electrolyte tends to be a very flammable substance. In contrast, a solid electrolyte won’t leak, substantially reducing the risk of a fire or explosion in a severe accident.

If the electrolyte is solid, it also allows for a much greater energy density (in watt-hours per kilogram or Wh/kg) than a conventional lithium-ion battery with a liquid electrolyte. If all else is the same, this gives the potential for a solid-state battery powered EV to have much greater range than an EV powered by a liquid electrolyte battery design.

Alternatively, a carmaker adopting a solid-state battery could instead use a lighter, smaller volume battery to offer a similar range to an EV powered by a liquid electrolyte battery. This could yield benefits ranging from better packaging and greater interior and luggage space. With less weight to move, the carmaker might also realise improvements in performance and dynamics, such as better handling and acceleration.

The greater inherent safety with a solid electrolyte may also alleviate the need for the use of sophisticated battery cooling and monitoring systems, further reducing weight and removing packaging constraints.

Solid-state batteries may also offer improved charging speeds. Toyota, which holds over 1000 patents relating to the technology, claims that vehicles using solid-state batteries could charge from empty to full within 10 minutes.

Note that these benefits are currently all theoretical, and until a carmaker commercialises a solid-state battery vehicle, it will be impossible to objectively verify the practical benefits of the technology.

Although mass-produced already for applications such as pacemakers and other small devices, there remain numerous commercialisation challenges in manufacturing solid-state batteries suitable for electric vehicle use.

A key issue is temperature. It’s well-known that conventional liquid electrolyte, lithium-ion batteries perform worse at low temperatures. As a solid electrolyte has much more resistance, the problem is only compounded for a solid-state battery of the type and size necessary for EV usage. At present, solid-state batteries need to be heated to between 60-80°C to function effectively, making them unsuitable for cars that must work in cold weather.

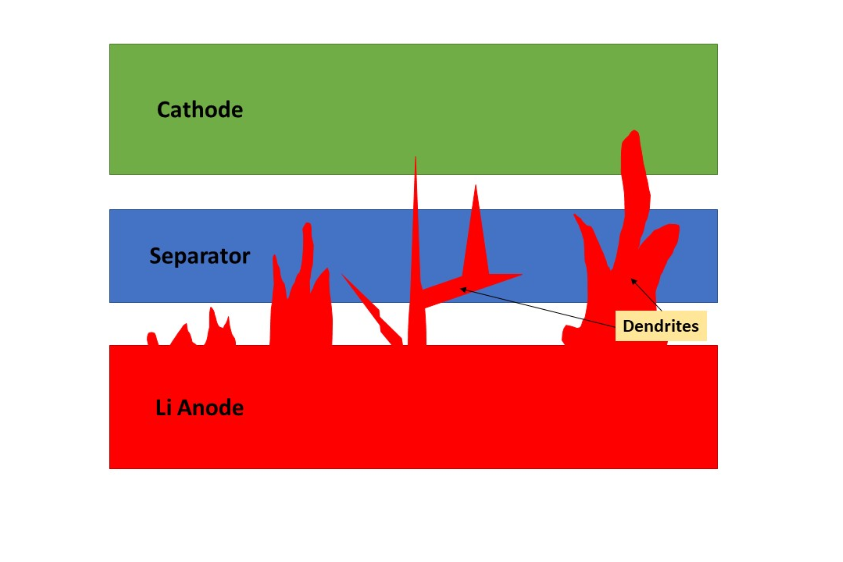

Longevity with regard to the number of charge cycles is another issue. Solid-state batteries have a tendency to form needle-like structures called dendrites on the surface of the anode, as the battery is discharged and recharged over time.

These dendrites can internally pierce the battery, creating a risk of the cell short-circuiting or otherwise malfunctioning and degrading its lifespan.

More practically, the materials and manufacturing processes required to develop these batteries at a large scale are significantly more expensive and complex than conventional lithium-ion cell production.

From a supply chain perspective, this also relates to ensuring the end-to-end process of mining the raw materials, transporting, manufacturing and then disposing of the batteries at the end of their lifespan remains sustainable. At present, no car manufacturer has been able to devise a cost-effective and sustainable recycling model for solid-state batteries.

Toyota is the car manufacturer that has arguably committed the most to solid-state batteries. The company has decided to invest almost US$14 billion in battery development until 2030, and as recently as September this year, has claimed that it has a working prototype of a solid-state battery EV currently being tested, and remains on track to introduce the technology by 2025.

It says it will use solid-state batteries first in hybrids as it has decades of experience with this setup, allowing for a faster path to production, and enabling it to gain customer feedback before rolling out the tech into its upcoming electric vehicles.

Other manufacturers have made smaller investments in the technology, or have made investments in start-ups aiming to further commercialise the technology. Volkswagen, for example, has made substantial investments in Silicon Valley solid-state battery start-up QuantumScape, whilst GM has not only received grant funding from the US Government to research the technology, but has also invested $139 million in another solid-state battery start-up, SES.

Ford, Hyundai and BMW have all also made in another solid-state battery player, SolidWorks, while Hyundai and Kia recently announced they were working with a US startup, Factorial Energy, to test the batteries in Hyundai Motor Group vehicles.

Factorial Energy says its batteries are safer and cost no more than lithium-ion batteries, while boasting 20 to 50 per cent longer range per charge. It also says its batteries can be produced on most existing lithium-ion battery manufacturing equipment. No timeline has been announced for when the batteries will appear in production vehicles.

There continue to be further ongoing innovations and technical developments to alleviate some of the commercialisation challenges associated with solid-state batteries. Researchers at Harvard University, for example, have designed a solid-state battery with a sandwich structure that can control dendrite growth, and potentially prolong battery longevity to at least 10,000 charge cycles. This could effectively result in the battery remaining functional for the lifetime of the car.

James Wong

6 Days Ago

James Wong

5 Days Ago

Max Davies

4 Days Ago

Josh Nevett

2 Days Ago

Max Davies

2 Days Ago

William Stopford

1 Day Ago