Anthony Crawford

1990 Lamborghini Countach review

6 Days Ago

How does AMG allow its performance battery to charge and recharge so rapidly? It's all in the packaging.

Publisher

Publisher

The all-new Mercedes-Benz C63 S E Performance features a complex power unit consisting of a 2.0-litre four-cylinder turbocharged engine combined with an electric drive unit that has a total output of 500kW and 1020Nm of torque.

You can read all about the powertrain here and read our review of the vehicle here.

What about the battery though? How does a relatively tiny 6.1kWh capacity battery work so effectively to provide 150kW of power and 320Nm of torque so consistently?

We spoke to Rene Szczepek, AMG’s head development driving dynamics engineer at the launch of the new C63 in Spain last month to find out AMG’s secret to rapid charging and discharging of energy from its battery.

“Battery cells are floated in oil, the complete battery is floated with oil to cool it. The magic in the battery is to be aware of hotspots and [to] take care that the whole system has a constant controlled temperature,” Mr Szczepek said.

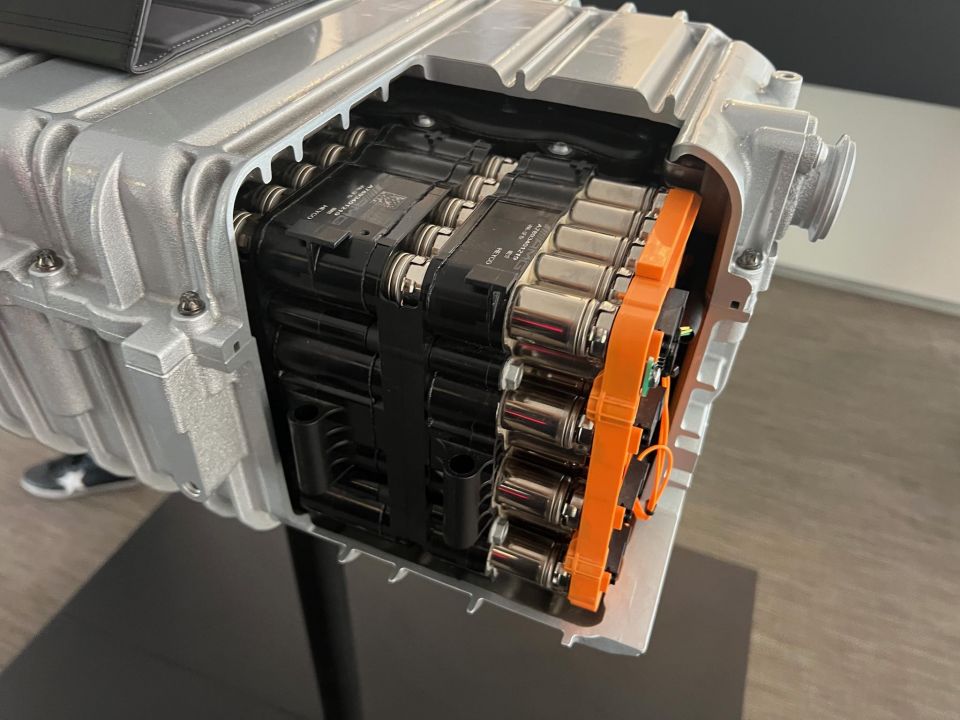

AMG engineers have developed a pack that is surprisingly large for the capacity of the battery. The reason for that is to keep the cells consistently cool in all situations.

Using about 14 litres of coolant oil, the battery cells (which are nicely spread apart) are immersed from top to bottom through the entire battery past each cell with an electric oil pump that passes the oil through the battery pack and then cools it via an oil/water heat exchanger.

This helps conduct the heat into one of the two low-temperature circuits (LT) of the vehicle. From there, it goes on to the LT cooler at the front of the car, which releases the heat into the ambient air. The system is designed to ensure even heat distribution in the battery.

According to Szczepek the optimum operating temperature window for the battery cells is 45 degrees celsius, which the system can maintain regardless of how often, or how vigorously the battery is charged or discharged.

When battery temperatures start to hit 60 degrees and above, protection mechanisms are activated so that maximum power can still be drawn from the battery in order to subsequently lower the temperature level again rapidly through direct cooling.

This means that even on a racetrack, the battery discharge and recharge can occur at rapid and repetitive fashion as the battery temperature is kept consistent.

“Electricity always goes the easiest way, and we have to be aware that all the cells in here are so damn good that as soon as you pull out your energy, the temp level of the battery will keep an average and the average is the cell temp of every cell will stay at the same level,” said Mr Szczepek.

The position of the cells is also a solution to the cooling, allowing the oil to pass through and remove the effective heat.

The battery system weighs 89kg with the oil and is sealed for life with no servicing required. AMG says it has managed to keep the weight down thanks to the material-saving busbar concept, and the lightweight aluminium housing.

As for why the battery pack is relatively large for it capacity, Szczepek says it was about performance rather than packaging.

“If you know where the battery hotspot is, you can say when to cut the electricity going out of the battery. This is why we decided to go for a step and are not package-focused to be honest, there is lots of holes, we have a big gap between cells but we decided actively to do so because if we just wanted a capacity of 6.1 [kWh] and got it as small as possible, that thing won’t work as it does right now.

“So we needed to go like they do in Formula 1, you need to cool everything, every single cell with a very high amount of oil floating through the battery and have it actively cooled.”

The Mercedes-AMG C63 S E Performance has an electric-only range of 13km.

Where expert car reviews meet expert car buying – CarExpert gives you trusted advice, personalised service and real savings on your next new car.

Alborz is the founder of CarAdvice (sold to Nine and now Drive) and co-founder of CarExpert. He is an honourary adjunct professor & entrepreneur in residence at the University of QLD. He loves naturally-aspirated V8s, V10s and V12s and is in denial about the impending death of the internal combustion engine. The best way to reach him is via Instagram.

Anthony Crawford

6 Days Ago

Matt Campbell

5 Days Ago

James Wong

4 Days Ago

Max Davies

2 Days Ago

Josh Nevett

1 Day Ago

Josh Nevett

19 Hours Ago