Max Davies

2026 GWM Cannon Ultra review

6 Days Ago

Formula 1 is well-known for its glory and drama, but what’s perhaps less known are the innovations that have been proven on the track and have trickled down to road cars.

Contributor

Contributor

While the Netflix series Drive to Survive has put a spotlight on the drama, rivalries and intense competition in Formula 1 that occurs between drivers, teams and their owners (alongside a dash of stating the obvious by Will Buxton), there has arguably been less of a focus on the actual technologies used by the cars.

Some of these innovations, including materials and aerodynamic and suspension components, have not only yielded victories on the track but have also made their way into everyday road cars.

Weight reduction works hand-in-hand with aerodynamics in maximising performance on the track.

Formula 1 cars such as the Lotus 88 and McLaren MP4/1 revolutionised the art of reducing weight without compromising the vehicle’s rigidity or structural integrity through their use of carbon fibre.

Although carbon fibre had been invented in the late 1950s, it had seen limited practical application in the automotive context.

Well-known for offering an ideal combination of incredible stiffness and low weight compared to steel, the Lotus 88 and McLaren MP4/1 were the first Formula 1 cars to extensively use this material, with the MP4/1 featuring a single-piece carbon fibre monocoque chassis.

In fact, a widely held belief is that McLaren driver John Watson was able to survive his crash at the Italian Grand Prix due to the stiffness of the carbon fibre monocoque that his car used.

Today, carbon-fibre components are commonplace in prestige and performance vehicles as they continue to deliver weight and stiffness benefits over metal alternatives. Performance vehicles such as the BMW M3 and M4, and even grand tourers such as the Lexus LC, are available with carbon-fibre roofs that reduce mass and also assist in improving overall vehicle handling by lowering the car’s centre of gravity.

Other sports sedans such as the Alfa Romeo Giulia and more affordable sports cars such as the new Nissan Z make use of carbon fibre components such as a carbon fibre propeller shaft (Giulia) and drive shaft (manual-equipped versions of the Nissan Z).

One of the few non-performance cars at a relatively affordable price point to follow more closely in the footsteps of the MP4/1 and the Lotus 88 is the recently discontinued BMW i3. The chassis, known as the ‘Life’ module in BMW’s LifeDrive architecture, is a capsule made entirely from carbon-fibre reinforced plastic (CFRP), with special adhesive and production processes such as resin transfer moulding (RTM) being used to join the CFRP parts.

Of course, McLaren’s current road car range also makes extensive use of the material, and continues to follow more directly in the footsteps of their F1 ancestors.

The brand’s latest model, the Artura, features the new McLaren Carbon Lightweight Architecture (MCLA) monocoque chassis that is also optimised for hybrid powertrains, and weighs just 82kg, despite including crash structures and load-bearing paths.

Aerodynamics also play a crucial role in Formula 1 cars, with large rear spoilers, front wings and numerous other components all playing their part in reducing lift and maximising downforce, to ensure that an F1 car’s tyres are pushed firmly into the tarmac at all times, helping to maximise cornering speeds and reduce braking distances.

The use of large, functional diffusers also helps to develop a ground effect, shaping the air to create a low-pressure field that sucks the car to the road.

Brabham’s BT46B made innovative use of another technology to maximise this ground effect, namely a fan. Engineered by Gordon Murray and making its debut at the 1978 Swedish Grand Prix, the BT46B featured a fan mounted within its tail that would be powered by the car’s flat-12 Alfa Romeo engine.

F1 regulations at the time stipulated that cars could not have any moving parts to enhance aerodynamics, and so the fan’s primary purpose was to cool the engine’s radiators. However, as an ostensible side effect, the fan also sucked air in to generate a substantial ground effect, helping driver Niki Lauda win the Swedish GP.

While F1-inspired large rear spoilers and diffusers are used by many supercars today, Gordon Murray Automotive’s (GMA) road-legal T50 hypercar also makes use of a similar tail-mounted fan, now powered by a 48-volt motor. GMA claims that the fan actively manages underbody and overbody airflow, helping to create the right balance between drag and downforce at all speeds.

Notably, the famed McLaren F1 supercar also made use of fan-assisted aerodynamics, although it featured two smaller fans hidden within the car’s bodywork.

Featuring an all-star roster that at various points included the likes of technical genius Adrian Newey, and drivers such as Nigel Mansell, Alain Prost and Ayrton Senna, Williams was one of the dominant teams in F1 during the 1990s.

Its success wasn’t due to just skilled drivers, however, with technological innovations also being a significant factor. One of these innovations was the computer-controlled active hydraulic suspension system pioneered by the Williams FW14B in the 1992 F1 season.

When taking a corner on a track, a car’s outside wheels experience greater forces than the inside wheels, making the cars imbalanced, introducing roll and thereby forcing the driver to slow down to prevent excessive understeer.

The active suspension system on the FW14B used high-pressure hydraulic components that could stiffen the suspension for the outside wheel during cornering, allowing for a level ride height that reduced roll and gave the driver more confidence to take corners at higher speed.

Additionally, the active suspension system could also drop the car’s ride height on straights to reduce drag and thereby increase top speed.

The results were clear, with the FW14B, driven by Nigel Mansell and Ricardo Patrese, winning 10 of the 16 Grand Prix in the 1992 F1 season. In fact, the technology was so successful that the FIA (the governing body of motorsport globally) banned it in Formula 1 competition for the 1994 season onwards.

Nevertheless, more sophisticated active suspension systems, also known as adaptive suspension, continue to feature heavily in road cars today.

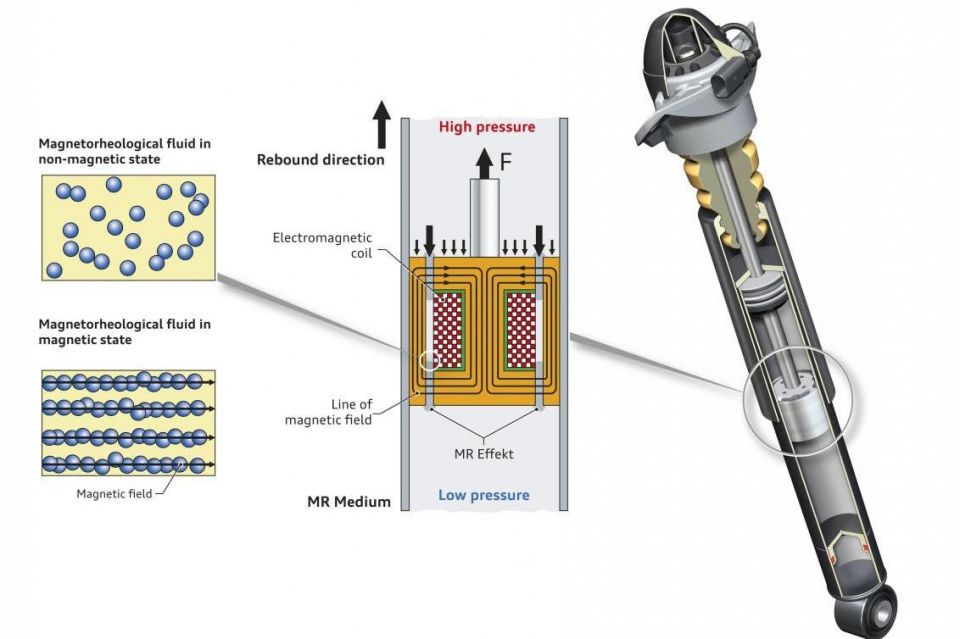

This includes systems that electronically control the suspension damping process, either through the use of motors to adjust the opening of the damper flow valve, or through the use of a magnetorheological fluid. This is a fluid with suspended metal particles, that can change its viscosity (thickness) in response to an electric current, allowing the suspension to be stiffened.

Examples of active/adaptive suspension systems in use today include DCC (Dynamic Chassis Control) in VW products, Alfa Romeo’s Alfa Active suspension, as well as Magnetic Ride Control (General Motors), MagneRide (Ford), Adaptive Dynamics (Jaguar), Porsche Active Suspension Management (PASM), Adaptive Variable Suspension (Lexus) and Four-C Chassis Control (Volvo).

Max Davies

6 Days Ago

Josh Nevett

4 Days Ago

Max Davies

4 Days Ago

Max Davies

3 Days Ago

Neil Briscoe

2 Days Ago

Max Davies

1 Day Ago